- good mixing and dispersion properties

- good extrusions properties

- high surface quality

- high electrical resistance

- cost reduction potential

- avoid deposits on dies caused by filler

- lower water absorption (compared with carbon black)

soft, chemically foamed

- Sponge profile, electrically non-conductive, partial carbon black replacement; Density 0.50 g/cm³; EPDM; sulfur cure / CV cure (M 665.4/10) (M 665.4/9) (M 665.4/11) (M 665.4/14) (M 665.4/13)

- Door seal tube; Density 0.55 g/cm³; EPDM; sulfur cure / LCM cure (M 704)

- Sponge profile, electrically conductive, partial carbon black replacement; Density 0.50 g/cm³; EPDM; sulfur cure / CV cure (M 665.4/4) (M 665.4/2) (M 665.4/1) (M 665.4/7) (M 665.4/6) (M 665.4/3)

- Profile; Density 0.30 g/cm³; EPDM; sulfur cure / LCM cure (A.2.0.002) (A.2.0.001)

- Smooth skin, excellent load deflection; Density 0.50 g/cm³; EPDM; sulfur cure / UHF cure (S 8943)

- Door seal tube; Density 0.55 g/cm³; EPDM; sulfur cure / LCM cure (M 701)

- Expanded parts of snap-on profile for bonnet and trunkseals, good collapse resistance; Density 0.60 g/cm³; EPDM; sulfur cure / UHF cure (V 2658)

hard, physically foamed

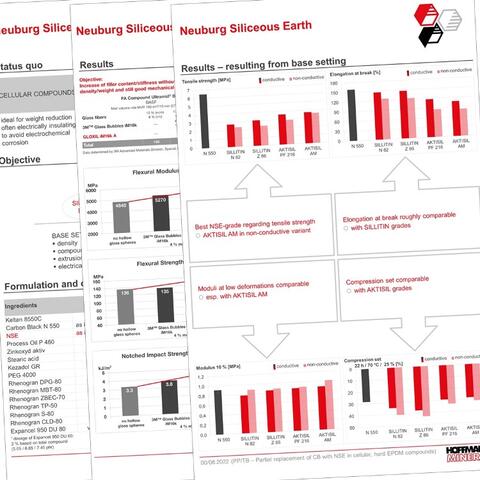

- Profile, cellular, hard, electrically conductive, partial carbon black replacement for weight and cost savings; 60 Shore A; Density 0.70 g/cm³; EPDM; sulfur cure / CV cure (M 680.4/15) (M 680.4/14) (M 680.4/12) (M 680.4/11) (M 680.4/1)

- Profile, cellular, hard, electrically non-conductive, partial carbon black replacement for weight and cost savings; 60 Shore A; Density 0.70 g/cm³; EPDM; sulfur cure / CV cure (M 680.4/6) (M 680.4/2) (M 680.4/5) (M 680.4/3)