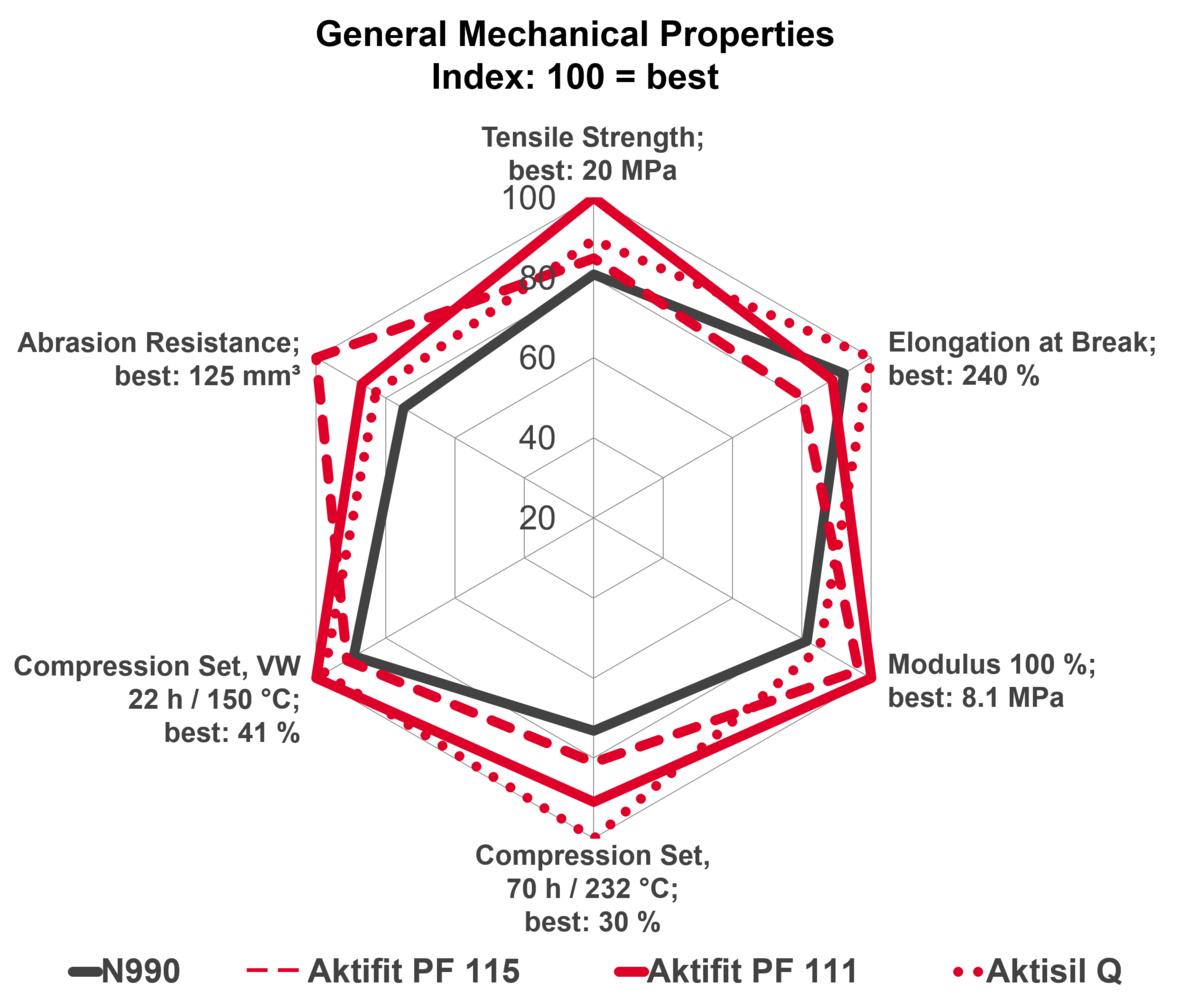

Fluoro polymers are generally known for high resistance against heat and chemicals. Therefore, they are preferred for joints and conveying systems for chemicals where the properties of other polymers are no longer sufficient. By using fillers it is possible to improve the property profile of fluoro carbon elastomers. Until now, either carbon black N990 or mineral fillers such as wollastonite or barium sulfate have been used. Different grades of Neuburg Siliceous Earth have been compared with these traditionally used fillers in bisphenolic cured FKM, including examples for pertinent applications.

ADVANTAGES OF USING NEUBURG SILICEOUS EARTH

- very low sieve residue

- good mixing and dispersion properties

- high tensile strength

- high abrasion resistance

- long flow time with short vulcanization time

- good resistance to substance

- low compression set

- easy deflashing

- avoidance of mold fouling on dies caused by filler

Recommended Products

Calcined product, amino functionalized.

| Article Nr. | Aktifit PF 115 |

|---|---|

| field.surfaceModification | amino |

| field.basicMaterial | /(shared)/(produkt)/silfit/silfit-z-91-silfit-z-91 |

| field.particleSize50 | 2.3 |

| field.colorValueL | 95.7 |

Calcined product, alkyl functionalized.

| Article Nr. | Aktifit PF 111 |

|---|---|

| field.surfaceModification | alkyl |

| field.particleSize50 | 2.3 |

| field.colorValueL | 96.3 |

Calcined product, methacrylic functionalized.

| Article Nr. | Aktifit Q |

|---|---|

| field.surfaceModification | methacrylic |

| field.basicMaterial | /(shared)/(produkt)/silfit/silfit-z-91-silfit-z-91 |

| field.particleSize50 | 2.3 |

| field.colorValueL | 96.3 |